DUCTILE IRON PIPE

Specifications:

1) The standard of pipe: ISO 2531, EN545 , EN598.

2) Pipe class: K9, C40, C30, C25, etc.

3) Pipe joint: push-on joint(Tyton joint), K type joint, self-restrained joint

4) Effective length: in general, the pipe length is 6m for bulk shipment and 5.7m for container shipment.

5) Internal lining: cement mortar lining as per ISO4179

6) Zinc coating: at least 130g/m2 as per ISO 8179

7) Bitumen painting: at least 70um as per ISO 8179

8) Gaskets are NBR rubber, natural rubber, SBR rubber or EPDM rubber ring as per ISO4633

9) DN 80 - 2,600 mm

10) High strength, lighter than gray iron, good corrosion resistance, no furring, small flow resistance, easy fixing, long life time

11) Checked by automatic inspection equipment

12) Chemical composition: (%)

a) C: 3.5 - 4.0

b) Si: 1.9 - 2.6

c) Mn:0.15 - 0.45

c) P: <0.06

d) S: <0.02

13) Mechanical properties

a) Tensile strength: ≥420MPa

b) Yield strength: ≥300Mpa

c) Hardness: ≤230HB

d) Elongation%: DN80 - 1000 ≥10 DN1200 - 2200 ≥7

14) Process and testing:

a) Induction furnace and treated metal (Chemical analysis of raw material, spheroidizing & Nodularity)

b) Casting (Visual check and weight check)

c) Heat treatment (Micro structure)

d) Hydrostatic test (Pressure test)

e) Dimensional checks (Checking pipe length and joint, OD, wall thickness, appearance)

f) Zinc spraying (Thickness testing)

g) Lining and coating (100% visual check, thickness testing randomly)

i) Marking and packing (100% visual check)

15) The pipe coating can be customized, such as, zinc-aluminum alloy, PU, etc.

Packing: bundled with steel belts or in bulk

Shipment: in bulk or container

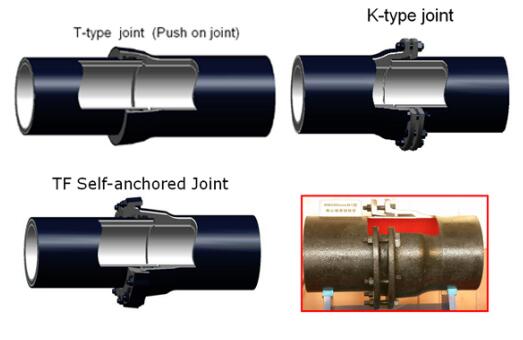

JOINTS

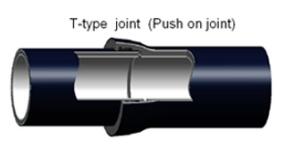

1. Push-on Joint (T-type Joint)

The T-type joint designs incorporate a single rubber sealing gasket assuring a tight, permanent seal. The "push-on" type joint is easy to assemble and fast to install. The push-on design eliminates the need for glands and fasteners. The rubber gasket fits inside the contour of the bell socket, which seats the gasket.The plain-end (spigot) of each pipe is beveled to further ease assembly.

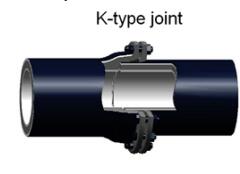

2. K-type Joint

The mechanical joint is a bolted joint utilizing a ductile iron gland and mechanical joint gasket. The mechanical joint is recommended for water service where many connections are required. All components of the mechanical joint are interchangeable. The spigot end of mechanical joint pipe has the same outside diameter as push-on joint pipe. As a result, it can be fitted into such joints in the field by beveling the outside edge. All of the accessories (glands and fasteners) are supplied with each joint.

3. TF Type Self-anchored Joint

Self-restrained Type is a push-in self anchored joint. The principle of joint anchoring consists in transmitting the axial forces from one pipeline to the following one, thus ensuring that the joint does not come apart.

The application of self-restrained joints is of particular interest where congested conditions preclude concrete anchor block constructions or in poorly cohesive soils.

Self-restrained joints combine the advantages of flexible joint pipes and welded joint pipes.

Self-anchored joints allow the axial thrusts arising at particular points (bends,

tapers, tees, blank flanges) to be distributed over one or more pipes, thus avoiding installation of concrete anchor blocks.

The seal is provided by a standard gasket.The axial force transmission is through a mechanical arrangement, independent of that providing the seal, comprising: